Design and Compliance – further explanation

Robust Details

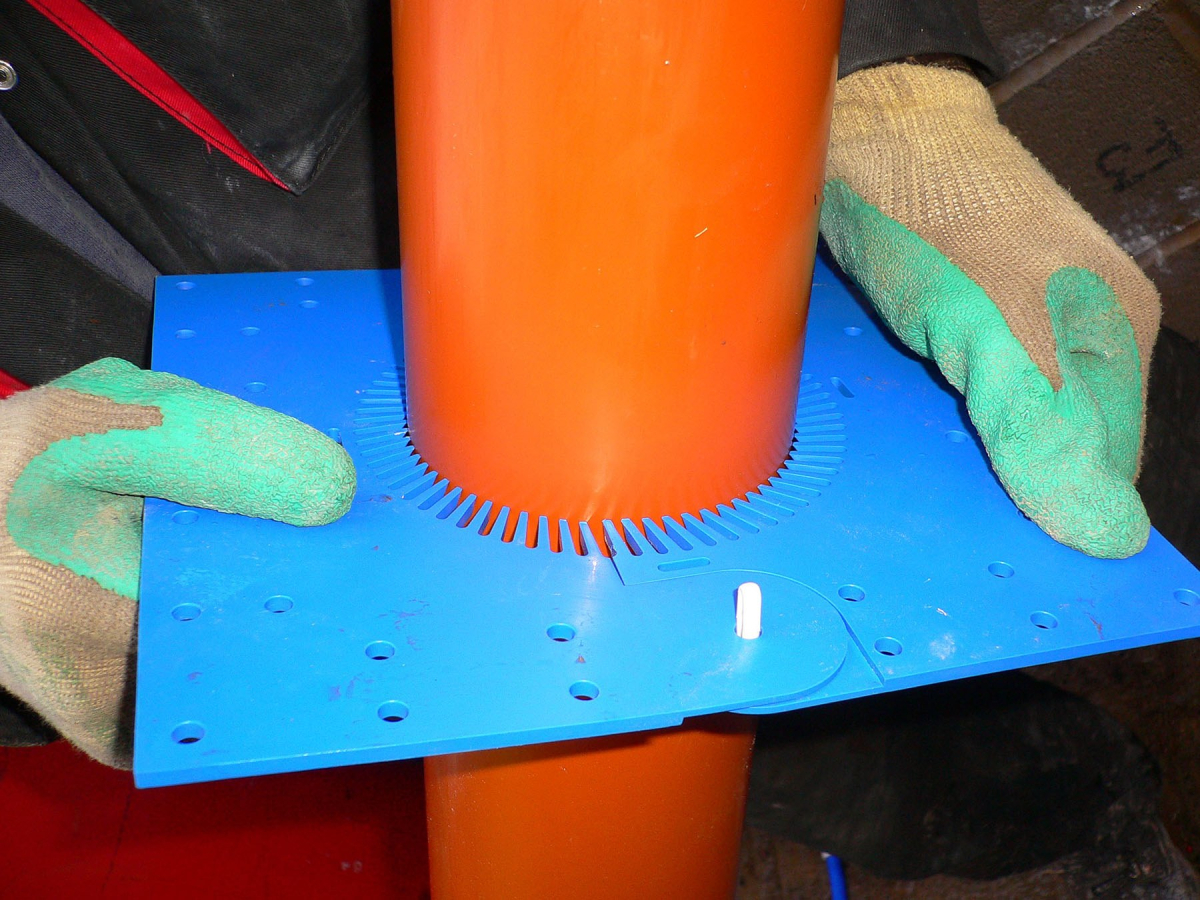

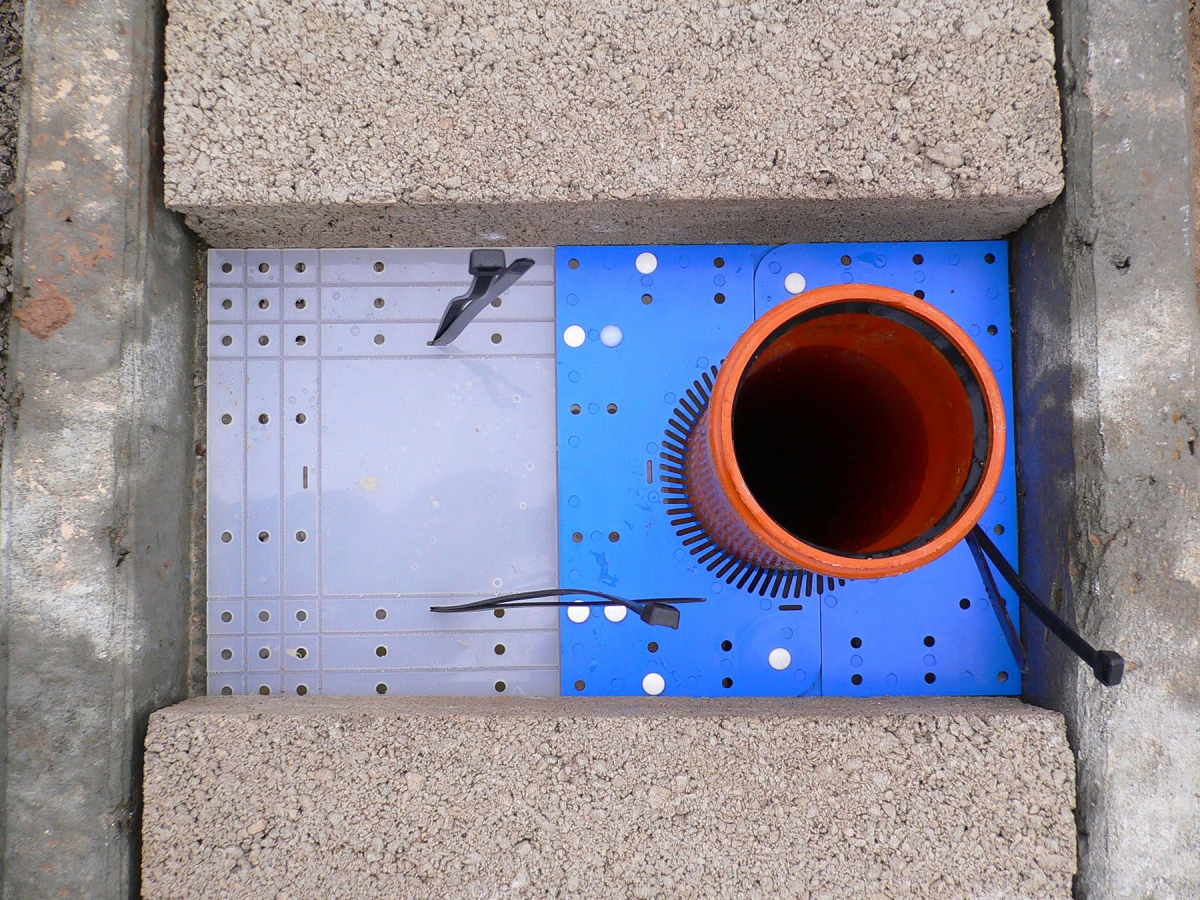

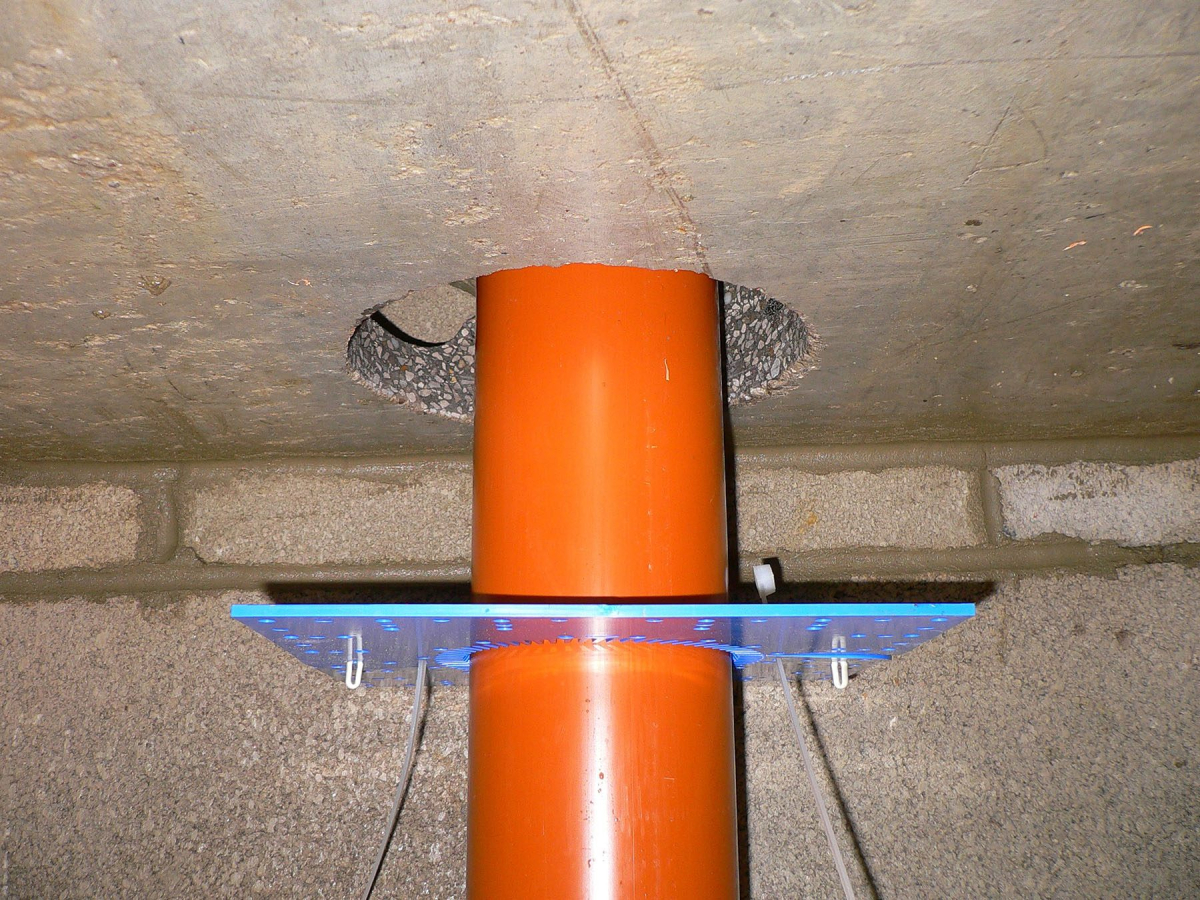

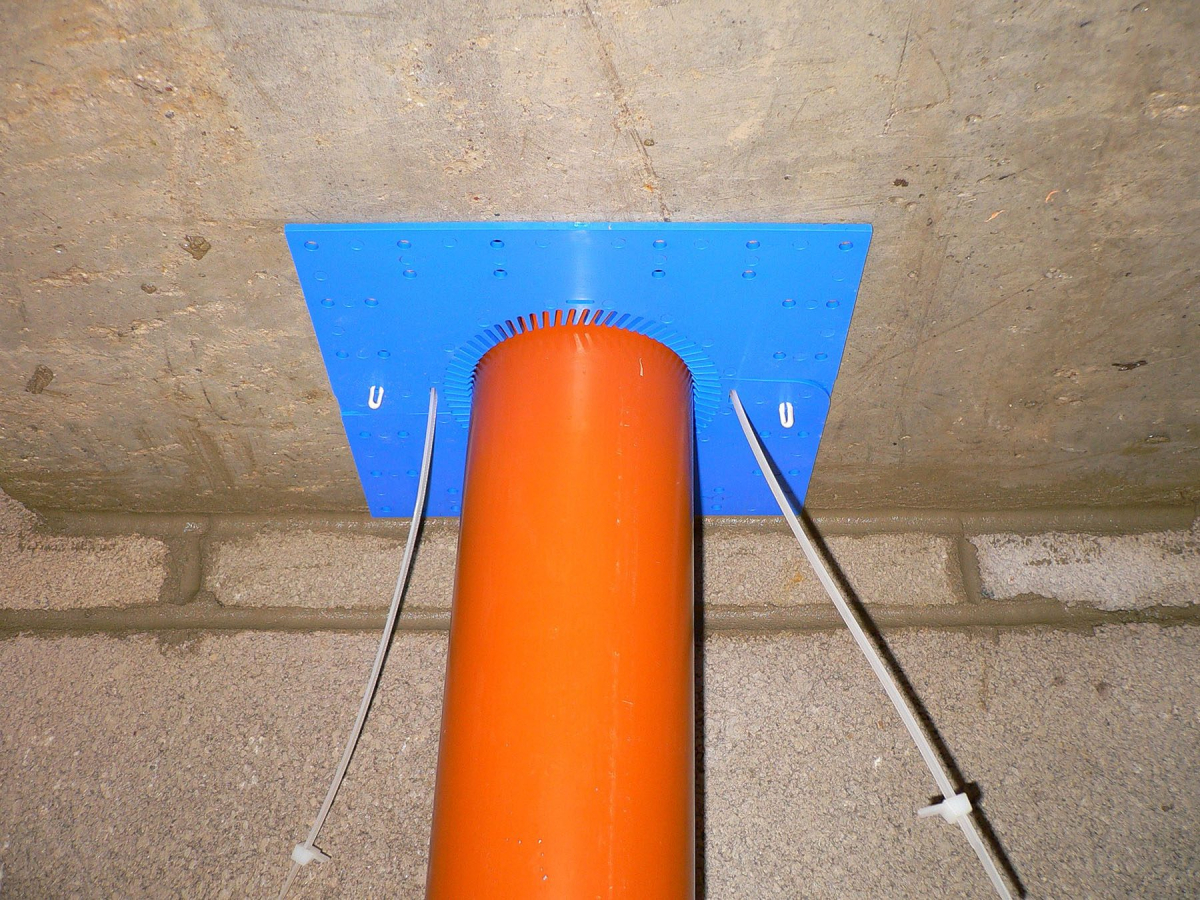

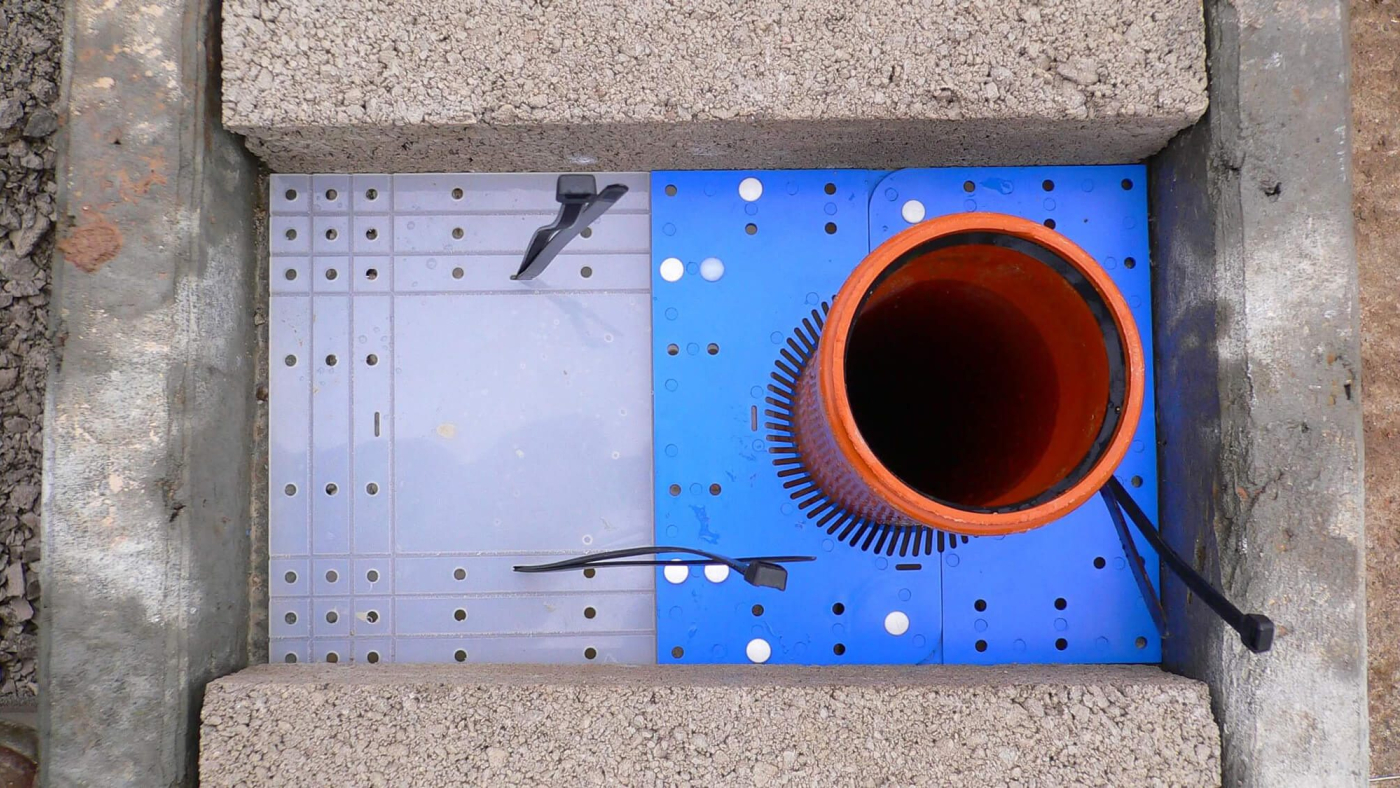

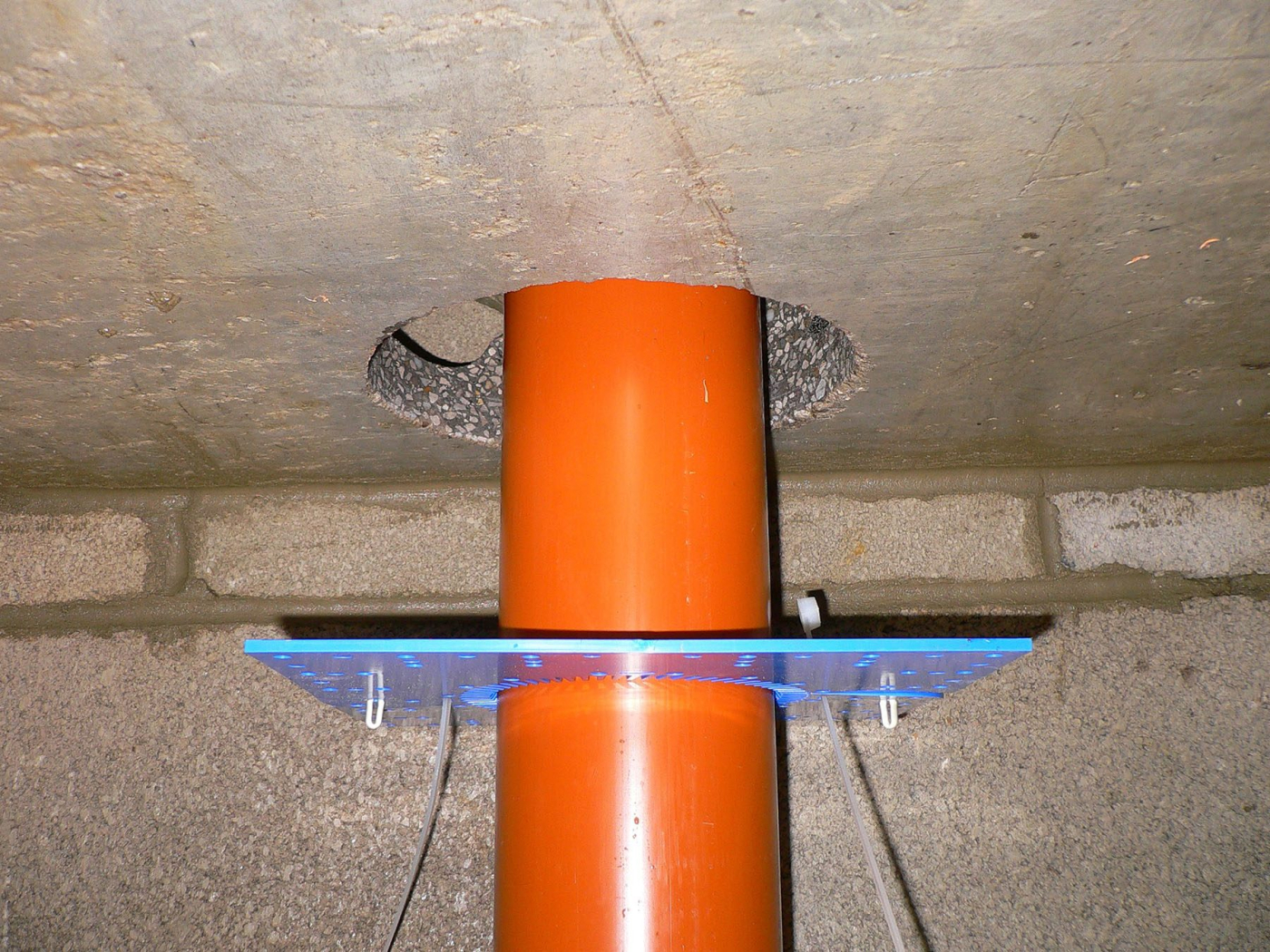

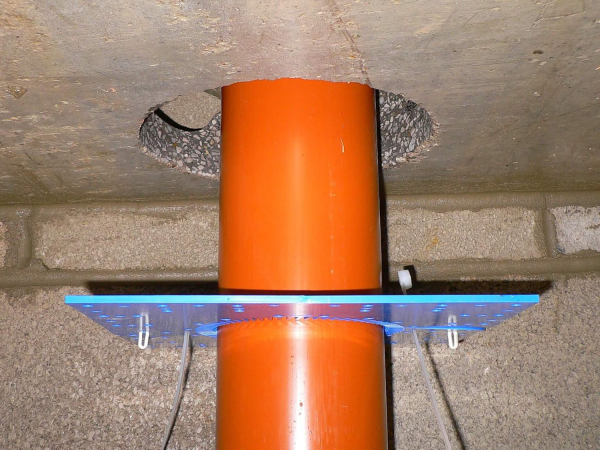

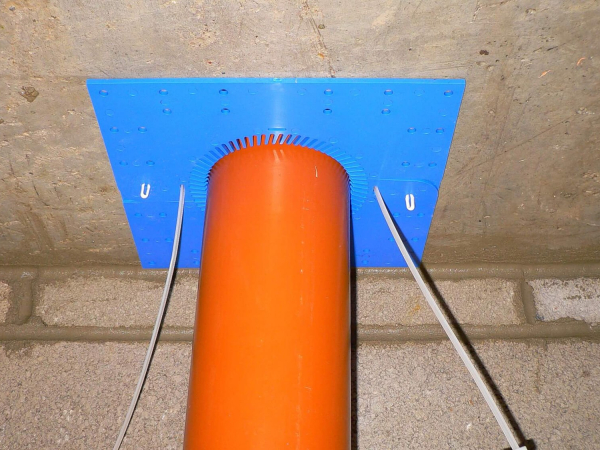

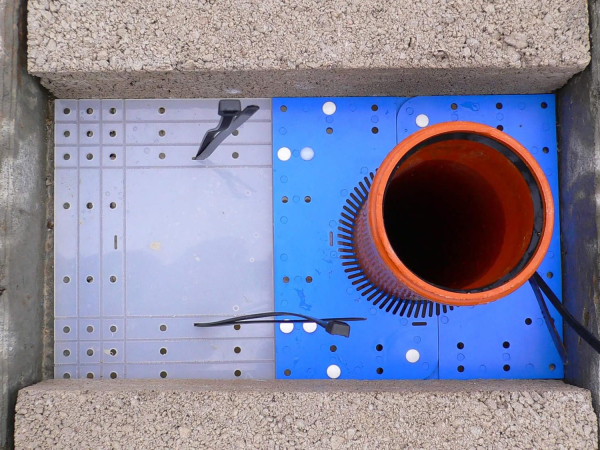

When building in accordance with Robust Details, it states that all voids around pipe should be sealed. The instant pipe shutter enables full depth seal, which complies with these requirements.

Approved Document B (Fire Safety)

In accordance with Volume 1, B3 Internal Fire Spread (Structure)

Construction of compartment walls and compartment floors

General provisions

5.8 All compartment walls and compartment floors should achieve both of the following.

a. Form a complete barrier to fire between the compartments they separate.

Section 9: Protection of Openings and Fire-Stopping

Openings for Pipes

Alternative A: Proprietary Seals (any pipe diameter)

9.3 Provide a proprietary, tested sealing system that will maintain the fire resistance of the wall, floor or cavity barrier.

In accordance with Volume 2 B3 Internal Fire Spread (Structure)

Section 8: Compartmentation/Sprinklers

Provision of compartmentation

All Purpose Groups

8.4 Effective compartmentation relies on both of the following.

b. Any openings between two compartments should not reduce the fire resistance.

Construction of compartment walls and compartment floors

General provisions

8.15 All compartment walls and compartment floors should achieve both of the following.

a. Form a complete barrier to fire between the compartments they separate.