Our Stadium Construction System was shortlisted in the 2024 British Construction Industry Awards and Building Innovation Awards. It’s made up of four modular solutions – Movement Bearer Grout Boxes, Fire Retardant Foam Grout Checks, Horseshoe Shims and Levelling Shims which are used on the development of sports and entertainment venues.

Typically, the four innovations are applied to the precast concrete terracing upstands, bearing locations and vomitory walls. These modular stadium products were used on Everton Football Club’s Bramley Moore Stadium. Manchester’s Co-op Live and celebrated landmark Basilica de la Sagrada Familia in Barcelona.

Cinemas and schools in the leisure and education sectors also have small amounts of precast terracing, but to a lesser volume of sports stadia.

What materials are used to build a sports venue stadium

Most sports venues, stadiums and arenas are built using steel structures and precast concrete, but sustainably sourced and recycled materials are gathering prominence. That’s why we chose recycled polypropylene and polystyrene for our Stadium System. These materials are reuseable, load rated, non-corrosive and lightweight. Weighing very little reduces their transport cost and environmental impact. Our plastic product manufacturers hold ISO9001 and are members of the British Plastics Federation.

The construction sector is realising there are better alternative systems which is why our stadia system creates real solutions to real problems. Robustly tested and tried in real-world conditions, it has been rapidly adopted by main contractors and end users including Laing O’Rourke, Severfield, Banagher Precast, EH Smith Builders, BAM UK, and Evans Precast, Billingtons and HARE.

Other projects our modular stadium products have been used on include Fulham Football Club, Wakefield Trinity Rugby Club, Anfield Main Stand, Wimbledon Court One, Emirates Stadium and Sandwell Aquatics (2022 Commonwealth Games).

What are new technologies in stadium development

The niche technologies we develop are based on simple designs and clever thinking to fix common industry problems. These four products come in different sizes and thicknesses.

- Movement Bearer Grout Boxes are used on the bearing stud to assist with movement caused by thermal effects. Made from polypropylene plastic it’s designed to fit over the projecting dowel bars located on the steel raker beam saddle, supporting the precast concrete terracing components.

- Fire Retardant Foam Grout Check is designed to seal joints to prevent grout loss to the precast concrete terracing bearing locations.

- Horseshoe Shims are designed to shim the vertical precast concrete components (vomitory walls) and made from polypropylene plastic measuring 130mm x 100mm.

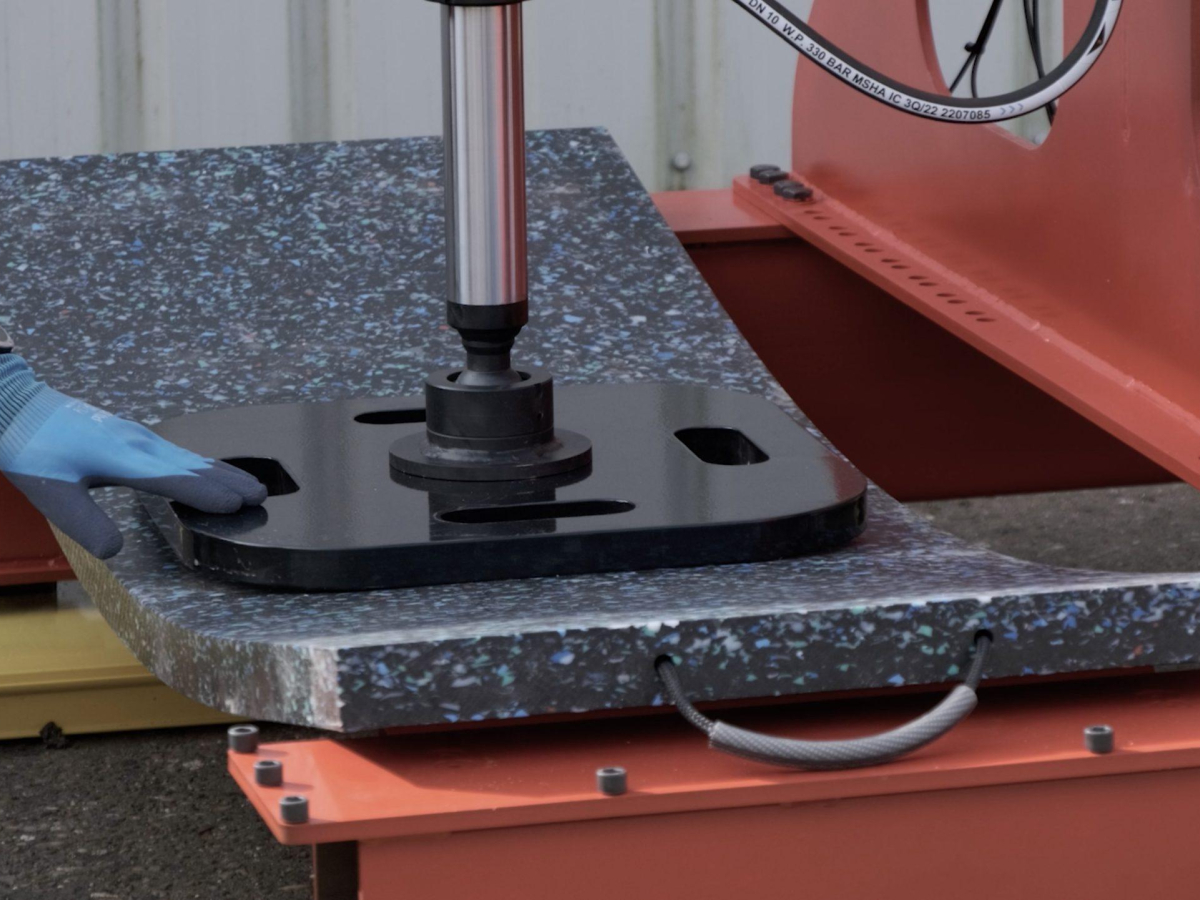

- Levelling Shims are used for precast concrete terracing upstands and bearing locations. These high impact polystyrene load bearing shims have a unique interlock which keeps the shim stack stable and locked into placed during installation. Adjustment is made away from the finger trapping zone and a side profile interlock allows the creation of larger load areas. The brand name for our levelling shims is Stacker Packers.

How do Foam Grout Checks work

Our fire-retardant Foam Grout Checks work by improving project efficiency. They make sure that when the grout is poured around the installed precast concrete terracing system, the gap between the supporting steel and the underside of the precast concrete terracing unit is bridged by the foam, ensuring no grout loss occurs.

How does a Grout Box work

The Grout Box is designed to allow lateral movement to mitigate the risk of the component cracking, but complying with the tie requirements associated with progressive collapse. It allows the precast concrete terracing components to expand and contract, which is caused by thermal effect.

What are Horseshoe Shims used for

Horseshoe Shims are used within the vertical tolerance gaps between precast concrete stadia components and left in-situ. Named after their shape, they are available in 10mm, 5mm, 3mm and 2mm thicknesses. It’s not necessary for Horseshoe Shims to be load rated, so using steel shims would be expensive and comparable to using a sledgehammer to crack a nut.

What are Levelling Shims used for

Levelling Shims or Levelling Packers are small square elements used to level surfaces in construction, usually precast concrete components such as stairs and terracing which are supported by a steel frame structure. They are also used to level modular elements like pods and cabins.

When Shims have to be load bearing the industry 'go to' solution is steel because of their high compressive strength. Our plastic levelling shims for stadium construction are also load bearing. With UV stabilisers each modular set overcomes the yellowing and brittleness linked with prolonged exposure to UV rays which is critical to performance. It’s a cheaper option than steel, lighter to carry, and load rated by independent testing laboratories.

Which stadiums are under construction

A story in The Times (July 2024) revealed that Saudi Arabia is planning ambitious growth with 15 new stadiums, and eight having at least 45,000 seats. Brilliant Ideas Ltd are already engaging with several new clients in the Middle East who have shown an interest in our award-winning sustainable innovations in construction.