Half-Loader Spreader Module launched at Vertikal Days

We were there! Vertikal Days two-day event at the East of England Showground, Peterborough opened this month.

It’s Europe’s largest lifting equipment exhibition, attracting around 2,500 visitors.

It’s always the perfect opportunity for us to meet our customers and welcome visitors to our stand. This year, we launched our Half Loader Spreader Module that’s designed to work with our ALIMATS® system.

It was great to work with Manitowoc and JT Cranes who also displayed a range of ALIMATS® modules under various machines on their stands. And – to get in the spirit of celebrating the King’s Coronation, we also painted a couple of modules to featuring the Union Jack.

Q & A - Half Loader Spreader Module

What’s its purpose?

To deliver a more even load spread, and higher safe working outrigger loads. It’s achieved by moving the load away from the centre of the mat system and spreading it across two locations – reducing pressure applied to the supporting ground. It’s designed to work in conjunction with our ALIMATS® system when high outrigger loads are present and removes the requirement for crane pads.[button link="https://brilliantideasltd.co.uk/alimats/videos/" text="Watch our Half Loader video"]

Is it handleable?

Is it handleable?

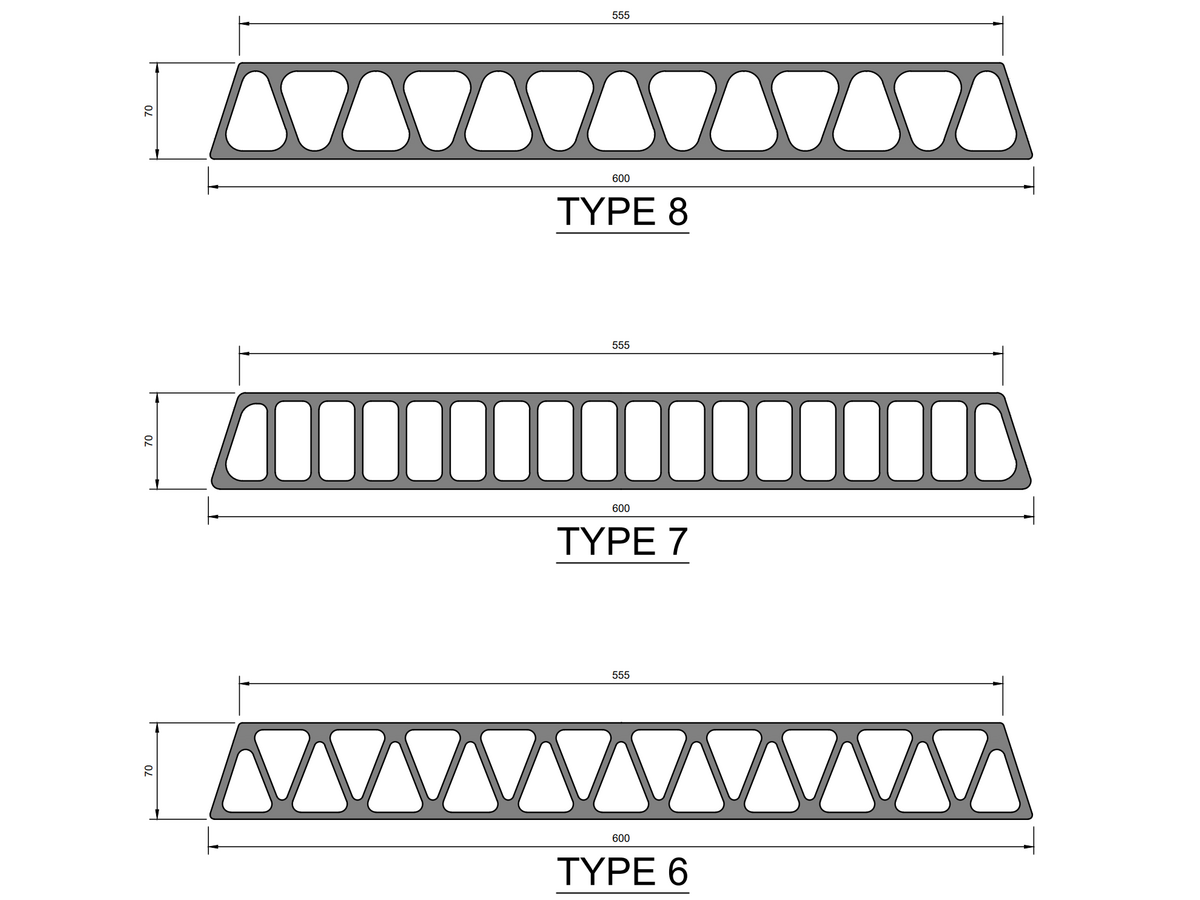

Just like every other mat module in our ALIMATS® range, the Half Loader is a lightweight Truss design weighing 48kgs, which is handleable for two people to offload, manoeuvre and position. It measures 1.16m.

Has it been tested?

Yes. It’s proven through independent Finite Element Analysis (FEA). As part of our development, we did a compression test on hard ground to ensure that smaller outriggers i.e., 100mm Ø wouldn’t punch through the profile. We also did a simulation test with a 100mm Ø load on the mat surface that went up to 75.37 tonnes (ultimate), which is an enormous load when you consider that the majority of crane outriggers are about 500 square (nearly 32 times larger surface area).

Who’s embracing it?

Who’s embracing it?

Right now, Temporary Works Engineers. We’re going to send these out on all our larger configurations from 6.05m² - and on configurations where the outrigger load is excessive. We’ve identified that there’s an inherent problem with a mats outrigger load being applied at the centre of the system.

What’s it made from?

Extruded aluminium. To be precise, its manufactured from EN AW 6005A-T6 certified high-grade recycled aluminium with CO2 per-life-cycle stage analysis. The new profile is even deeper than our standard ALIMATS® profile and three times stiffer.

Why did you develop it?

Why did you develop it?

We’ll let our Dan Westgate answer this one. It was brainchild of Dan and our Chris Massey when they had an impromptu meeting at Donington Services!"It’s part of our ongoing project in being able to define and achieve higher Safe Working Loads (SWL) based on our standard mat configurations. Mobile cranes are lifting more at greater distances and imposing heavier loads through their outriggers, so there’s a much greater emphasis on structural integrity and performance. During our research into how an outrigger mat system performs we realised that if you moved the outrigger load away from the centre of the outrigger mat system then the load would be better distributed below the mat surface".If you didn’t manage to get to Vertikal, you can still see our full range of modules here – and download our ALIMATS® drawings:

https://brilliantideasltd.co.uk/alimats/ To find out more please get in touch with the team on 01335 345111 or email enquiries@brilliantideasltd.co.uk

Is it handleable?

Just like every other mat module in our ALIMATS® range, the Half Loader is a lightweight Truss design weighing 48kgs, which is handleable for two people to offload, manoeuvre and position. It measures 1.16m.Has it been tested?

Yes. It’s proven through independent Finite Element Analysis (FEA). As part of our development, we did a compression test on hard ground to ensure that smaller outriggers i.e., 100mm Ø wouldn’t punch through the profile. We also did a simulation test with a 100mm Ø load on the mat surface that went up to 75.37 tonnes (ultimate), which is an enormous load when you consider that the majority of crane outriggers are about 500 square (nearly 32 times larger surface area).

Is it handleable?

Just like every other mat module in our ALIMATS® range, the Half Loader is a lightweight Truss design weighing 48kgs, which is handleable for two people to offload, manoeuvre and position. It measures 1.16m.Has it been tested?

Yes. It’s proven through independent Finite Element Analysis (FEA). As part of our development, we did a compression test on hard ground to ensure that smaller outriggers i.e., 100mm Ø wouldn’t punch through the profile. We also did a simulation test with a 100mm Ø load on the mat surface that went up to 75.37 tonnes (ultimate), which is an enormous load when you consider that the majority of crane outriggers are about 500 square (nearly 32 times larger surface area). Who’s embracing it?

Right now, Temporary Works Engineers. We’re going to send these out on all our larger configurations from 6.05m² - and on configurations where the outrigger load is excessive. We’ve identified that there’s an inherent problem with a mats outrigger load being applied at the centre of the system.What’s it made from?

Extruded aluminium. To be precise, its manufactured from EN AW 6005A-T6 certified high-grade recycled aluminium with CO2 per-life-cycle stage analysis. The new profile is even deeper than our standard ALIMATS® profile and three times stiffer.

Who’s embracing it?

Right now, Temporary Works Engineers. We’re going to send these out on all our larger configurations from 6.05m² - and on configurations where the outrigger load is excessive. We’ve identified that there’s an inherent problem with a mats outrigger load being applied at the centre of the system.What’s it made from?

Extruded aluminium. To be precise, its manufactured from EN AW 6005A-T6 certified high-grade recycled aluminium with CO2 per-life-cycle stage analysis. The new profile is even deeper than our standard ALIMATS® profile and three times stiffer. Why did you develop it?

We’ll let our Dan Westgate answer this one. It was brainchild of Dan and our Chris Massey when they had an impromptu meeting at Donington Services!"It’s part of our ongoing project in being able to define and achieve higher Safe Working Loads (SWL) based on our standard mat configurations. Mobile cranes are lifting more at greater distances and imposing heavier loads through their outriggers, so there’s a much greater emphasis on structural integrity and performance. During our research into how an outrigger mat system performs we realised that if you moved the outrigger load away from the centre of the outrigger mat system then the load would be better distributed below the mat surface".If you didn’t manage to get to Vertikal, you can still see our full range of modules here – and download our ALIMATS® drawings:

Why did you develop it?

We’ll let our Dan Westgate answer this one. It was brainchild of Dan and our Chris Massey when they had an impromptu meeting at Donington Services!"It’s part of our ongoing project in being able to define and achieve higher Safe Working Loads (SWL) based on our standard mat configurations. Mobile cranes are lifting more at greater distances and imposing heavier loads through their outriggers, so there’s a much greater emphasis on structural integrity and performance. During our research into how an outrigger mat system performs we realised that if you moved the outrigger load away from the centre of the outrigger mat system then the load would be better distributed below the mat surface".If you didn’t manage to get to Vertikal, you can still see our full range of modules here – and download our ALIMATS® drawings: